N-Type TOPCon Solar Module

Gautam Solar’s Newly Launched N-type TOPCon Solar Modules utilize revolutionary TOPCon technology. In TOPCon Solar Cell, a thin tunneling oxide layer is applied on an N-Type Silicon Substrate, followed by a layer of highly doped Poly Silicon and Passivated Contacts. The tunnel oxide layer allows charge carriers to pass while minimizing recombination losses. The passivated contacts reduce surface recombination. This technology offers industry-leading module power and efficiency.

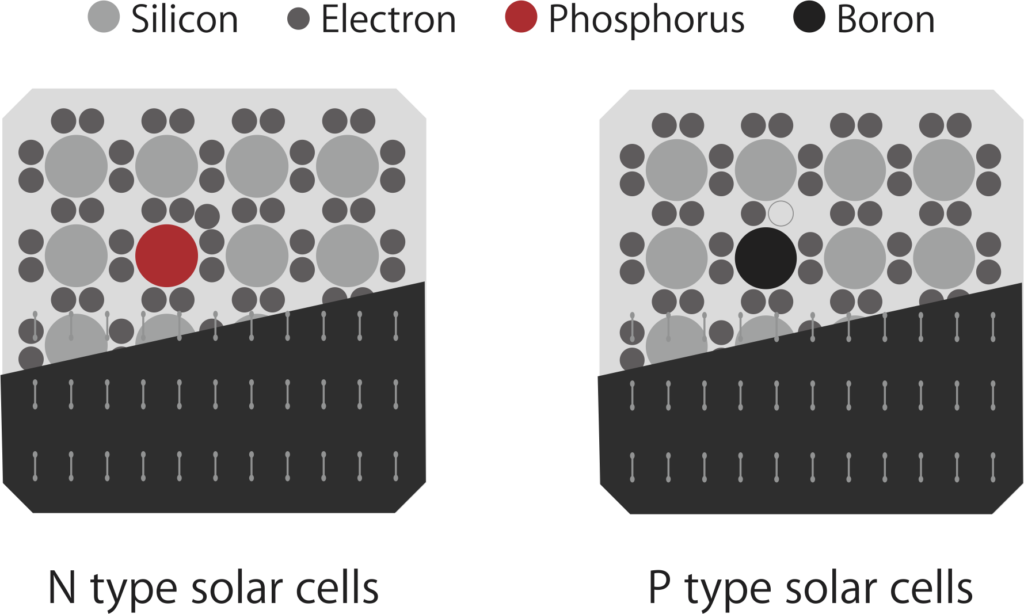

N-type Cells for Higher Efficiency

With P-type Cells, the base silicon layer is doped with boron, which creates an electron hole and positive charge carriers dominate. On the other hand, in N-type Cells, the base layer is doped with phosphorus. This generates free electrons which provide higher efficiency.

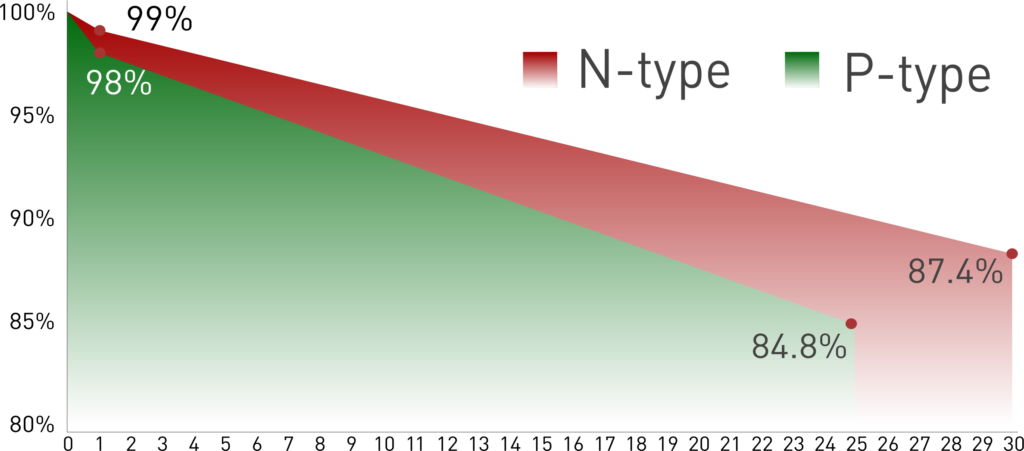

N-type TOPCon Structure for Lower Degradation

Gautam Solar’s N-type TOPCon Solar Modules have lower degradation rates of 1% in the first year and 0.4% YoY compared to 2% in the first year and 0.55% YoY for P-type Modules. Hence, Gautam Solar’s N-type TOPCon Modules degrade only to 87.4% after 30 years compared to P-type modules which degrade to 84.8% after 25 years.

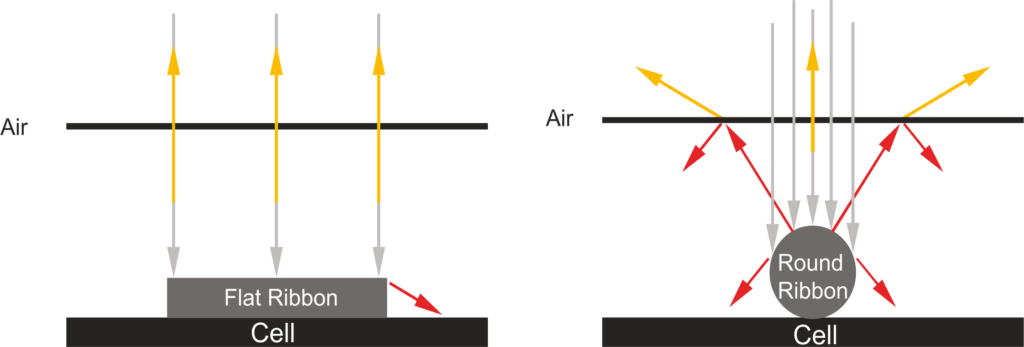

Round Ribbon for Higher Light Utilization

Using Round Ribbon Connectors, Gautam Solar’s N-type TOPCon Solar Modules are able to attain higher light utilization (up to 70% of the light falling on the ribbon is converted) compared to flat ribbon (only 5-10% light on the ribbon is converted) due to multiple reflections from the ribbon and glass.

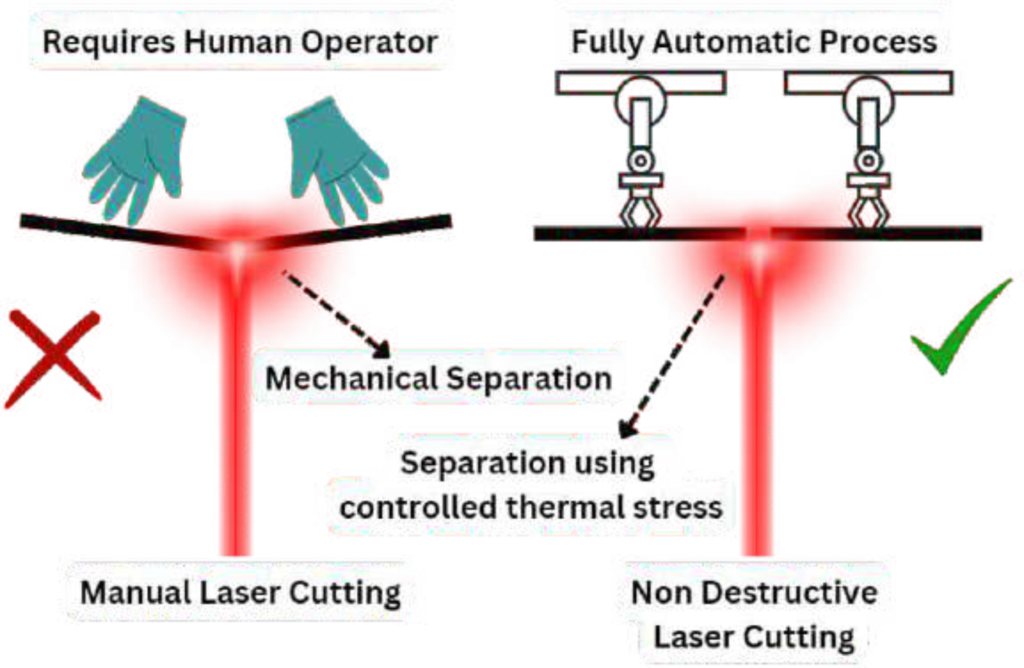

Non-Destructive Cell Cutting for Lower Stresses

Gautam Solar’s N-type TOPCon Solar Modules utilize Half-Cut Cells produced using Non-Destructive Cell Cutting (NDC). In this process, no heat-affected zone is formed and the half cells are separated using controlled thermal stress.

- Bigger M10 N-type TOPCon Solar Cells for higher wattage01

- 144 Half-Cut Cells for better performance in low light02

- Multi-Busbar Structure for Lower Electrical Losses 03

- Non-Destructive Cell Cutting Process for lower chances of micro-cracks 04

- Round Ribbon Connectors for better utilization of light 05

- 06Available in Monofacial and Bifacia

- 071% Degradation in first year and 0.4% Degradation in subsequent yeal

- 083.26% BOS Cost Savings

- 091.56% Reduction in LCOE

- 10Excellent Anti-PID Performance